Panasonic CF1 and CF2 automotive connectors

Usage of FPC for Automotive Battery Monitoring System is gaining more popularly over wire harness. FPC contribute to lighter weight and more flexibility in design. Panasonic has both wire and FPC connectors. In this article, we will focus on FPC connectors. Panasonic CF1 and CF2 connector are designed for various automotive applications (Example EV Battery management system, LED lighting system, other application which involved FPC). Panasonic FPC connectors have many advantages like robust, low profile, automatic soldering process (reflow solder), high operating temperature, CF2 connector able to meet automotive requirements like USCAR/LV214.

Features

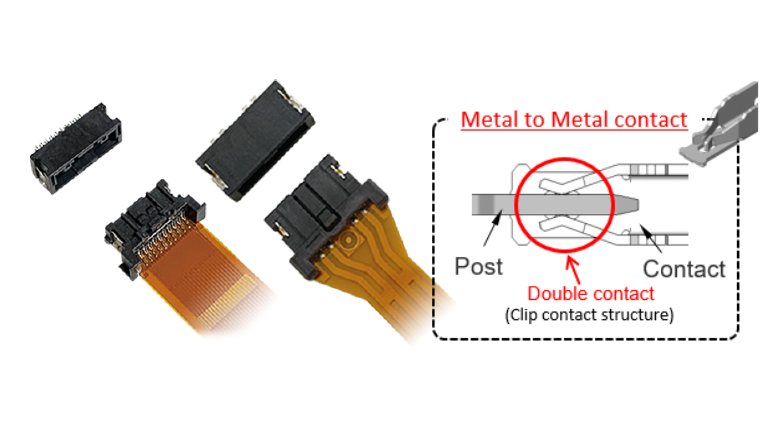

- CF1 and CF2 connectors enable the FPC to be directly connected to the PCB. There is no need for addition interface connector like wire harness connector. Board. CF1 and CF2 connectors can be reflow soldered thus adding convenience to assembly process.

- CF1 and CF2 connectors have metal clip contact structures in the plug which mated with metal posts- in the receptacle. This metal-to-metal contact enable good contact reliability and robustness (compare to other method like FPC crimping method or FPC-to-metal contact)

- CF2 connector able to meet automotive requirements like USCAR/LV214

- CF1 connector rating is Max 2A/pin. Available in 2,4,6,8 and 10 pins. Creepage distance 1.40mm

- CF2 connector rating is Max 1A/pin. Available in 16, 20, 24, 28 and 32 pins. Creepage distance 0.8mm

- Operating temperature -40 to 125°C

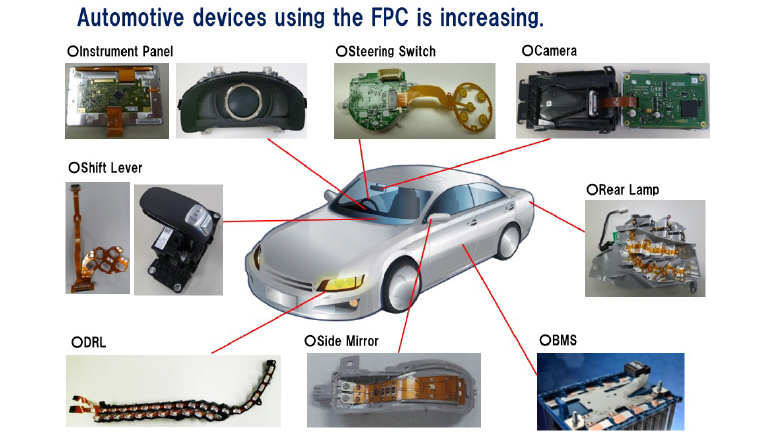

Applications

Automtove applications like BMS, LED lighting (headlamp, rear lamp, day light running lamp), applications with need of FPC.

Benefits

- Ease of assembly

- High reliability and robustness

- Low profile

Block diagram